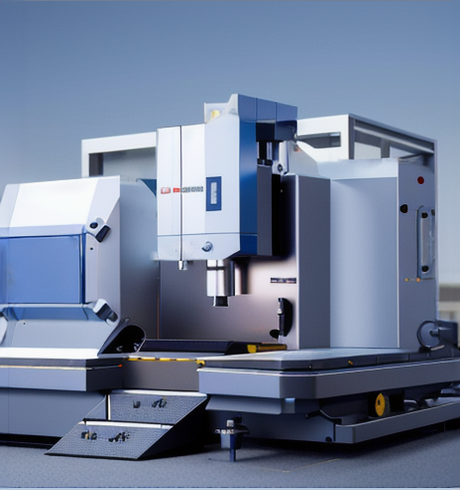

Machine tool

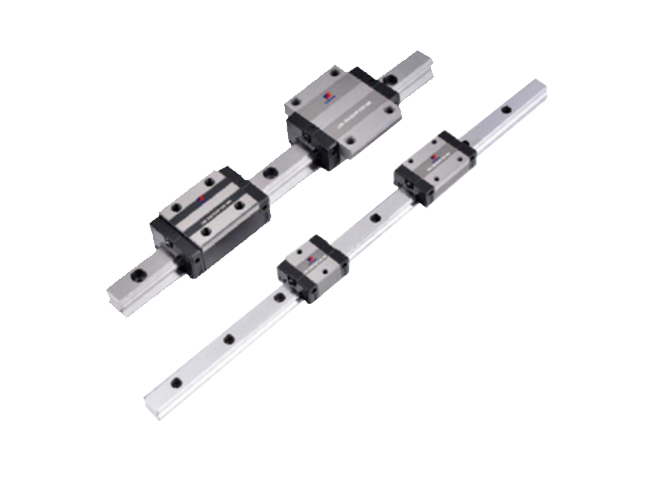

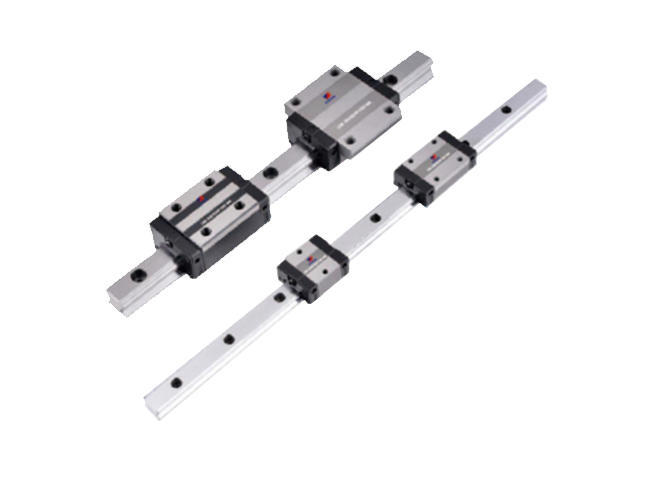

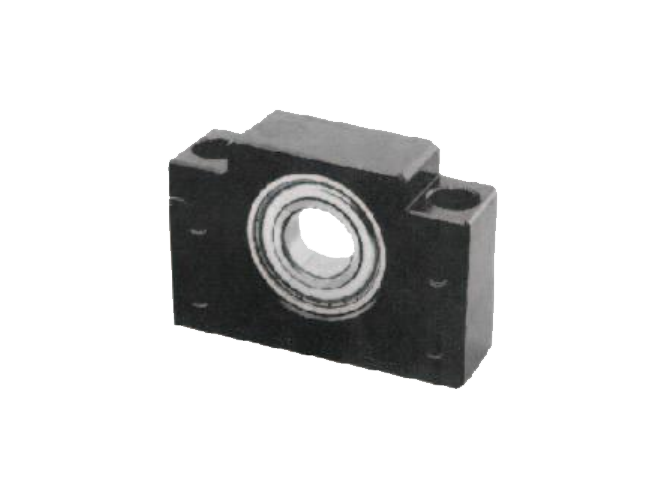

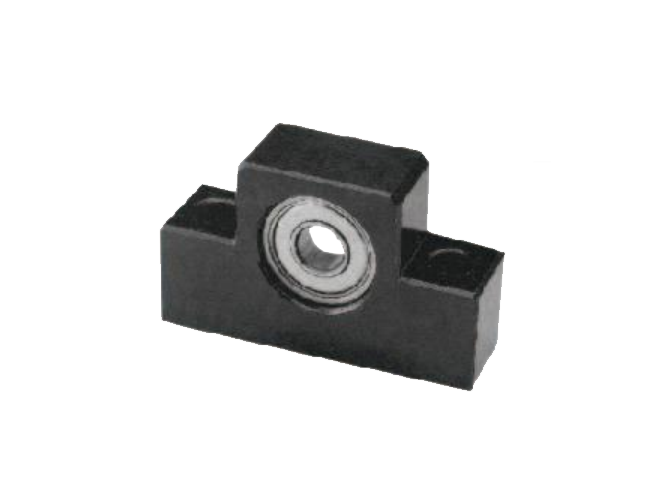

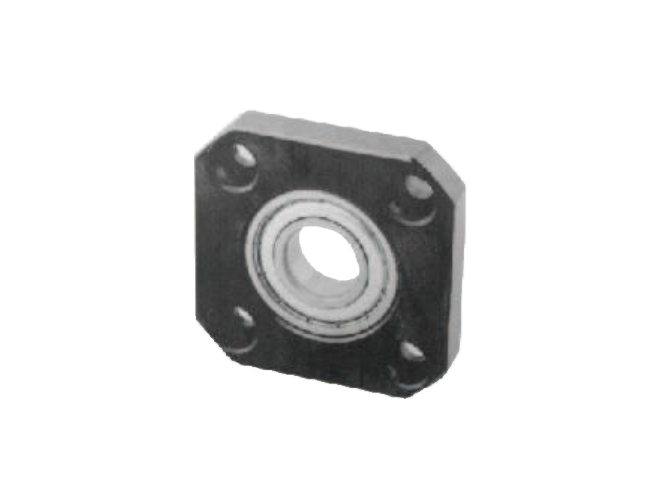

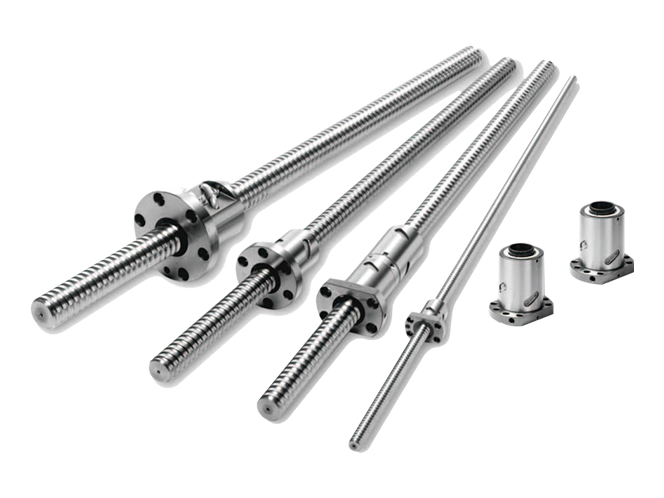

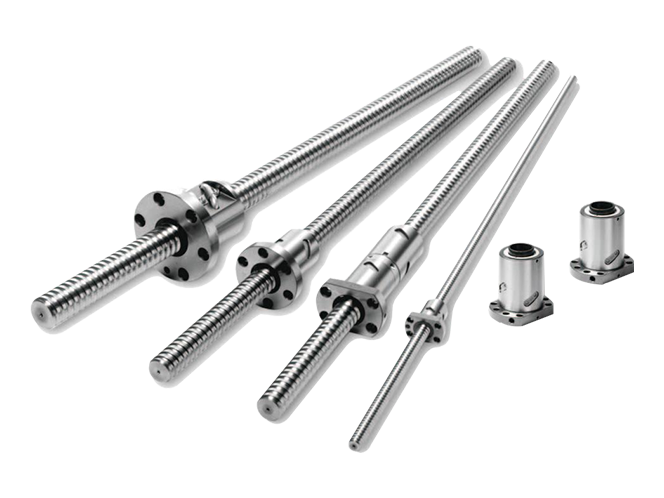

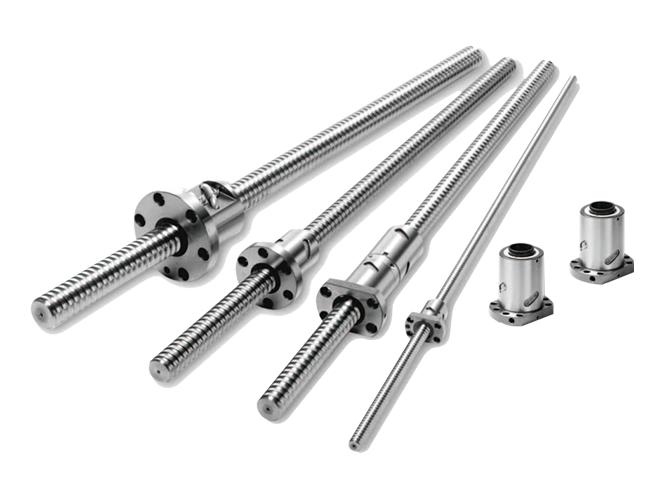

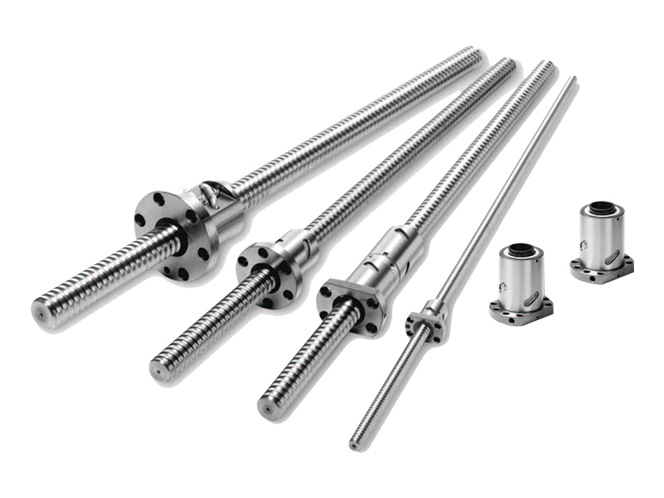

Ball screws and linear guides are two common mechanical transmission devices that play important roles in the industrial field. They each have unique characteristics and advantages, and often need to be combined in practical applications to improve positioning accuracy and repeatability.

In CNC machine tools, ball screws are often combined with linear guides to improve the positioning accuracy and repeatability of the machine tool. The ball screw is responsible for achieving precise rotation of the spindle, while the linear guide is used to control the linear motion of the workbench.

It has a wide range of applications in the industrial field. They have unique advantages in positioning accuracy and repeatability, and through collaborative application, the overall performance of the system can be further improved. In practical applications, the combination of ball screws and linear guides, as well as the corresponding control system design, need to be selected and optimized according to specific requirements to achieve the best results. The synergistic application of ball screws and linear guides will continue to play an important role in various fields and provide higher level support for industrial automation and precision control.

Contact us